What is Self-Priming Pump?

If a pump is located beneath the level of the liquid to be pumped, gravity and air pressure ensure that it is constantly filled with the liquid and there can be no ingress of air into the pump or suction line.

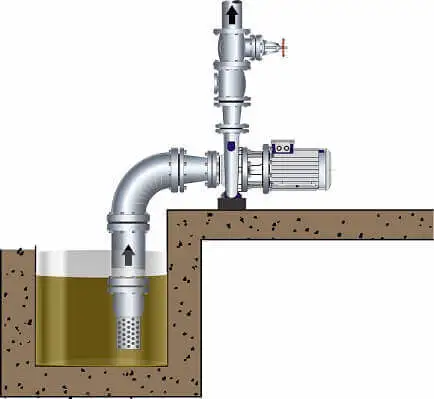

In many applications, a pump has to be placed above the level of the liquid, for example, when emptying an underground storage tank. At start-up, there will be air in the suction line and before the pump can discharge the liquid, this air must be evacuated or displaced. Pumps are optimised to move a particular liquid; evacuating a gas is a very different challenge.

Various methods can be used to get around this problem. A secondary pump can be used to evacuate the suction line. A non-return (foot) valve or evacuation tank can be used to stop fluid draining from the suction line when the pump is stopped. However, these solutions all involve extra equipment, piping and processes. Ideally, for these applications, a pump is required that can evacuate air from the suction side at startup before commencing its normal pumping mode. Such a pump is considered to be self-priming.

What Limits a Self-Priming Pump?

As a pump evacuates air from the suction side, liquid is forced into the suction line by the pressure of the surrounding air. This process can only continue until the head of liquid balances the local air pressure. With water, for example, it is theoretically possible for a perfectly efficient pump to self-prime to a height of only about 10m from its source. The precise limit is affected by altitude and temperature and will be different for other liquids.

Are Positive Displacement Pumps Self-Priming?

In principle, all positive displacement pumps are self-priming. In particular, this includes rotary gear pumps (internal and external), lobe pumps, vane pumps and diaphragm pumps. A common feature of all positive displacement pumps is the use of close-tolerance parts to prevent fluid from returning from the discharge to the suction side. Depending on the effectiveness of these seals created by these close-tolerance parts, a positive displacement pump is capable of venting air from its suction line to some extent. However, under dry running conditions, a pump may overheat and this can cause seal wear and pump failure.

With reciprocating pumps, there is also a danger of cavitation occurring at the point when liquid starts to enter the pump and there is a liquid/air mixture. Under these conditions, vapour bubbles form and expand on the suction side of the pump. Upon reaching the high pressure, discharge side of the pump, the bubbles collapse violently causing vibration and damage to the pumping elements.

For these reasons, it is important to refer to the manufacturer before using a positive displacement pump in an application where it must self-prime and, of necessity, be run dry for any period.

Are Centrifugal Pumps Self-Priming?

With centrifugal pumps, the pumping action is generated by the transfer of rotational energy from the impeller to the liquid. There are no seals between the suction and discharge sides of the pump. This means that centrifugal pumps are ineffective with gases and are not capable of evacuating air from a suction line when the liquid level is below that of the impeller. In such cases, the pump is said to be air-bound and there is a danger of overheating: generally, pumps rely on the pumped fluid to lubricate and cool the pump's bearings.

However, with a few modifications to the basic design, a centrifugal pump can be self-priming. The impeller and volute casing is essentially surrounded by a tank so that it can always be immersed in a liquid sufficient to get the pump started and provide the pump with lubrication and cooling-- provided the time taken to prime the pump is not excessive.

It is important that a self-priming centrifugal pump's reservoir is filled correctly with liquid after installation. "Self-priming" in this context means that the pump has the ability to use liquid stored in its housing to generate a vacuum on the suction line. Even a 'self-priming' centrifugal pump will not operate when dry. With appropriate bearings and seals, a centrifugal pump can tolerate dry running for a limited time but this is not recommended for extended periods.

How does a Self-Priming Centrifugal Pump Work?

A self-priming centrifugal pump has two phases of operation: priming mode and pumping mode.

In its priming mode, the pump essentially acts as a liquid-ring pump. The rotating impeller generates a vacuum at the impeller's 'eye' which draws air into the pump from the suction line. At the same time, it also creates a cylindrical ring of liquid on the inside of the pump casing. This effectively forms a gas-tight seal, stopping air returning from the discharge line to the suction line. Air bubbles are trapped in the liquid within the impeller's vanes and transported to the discharge port. There, the air is expelled and the liquid returns under gravity to the reservoir in the pump housing.

Gradually, liquid rises up the suction line as it is evacuated. This process continues until liquid replaces all the air in the suction piping and the pump. At this stage, the normal pumping mode commences, and liquid is discharged.

When the pump is shut off, the design of the priming chamber (normally involving a 'goose-neck' on the suction piping) ensures that enough liquid is retained so that the pump can self-prime on the next occasion it is used. If a pump has not been used for a while, it is important to check for losses from the casing due to leaks or evaporation before starting it.

What is a Compressed Air Self-Priming Pump?

It is possible to use compressed air, instead of a liquid charge, to prime a pump. Compressed air is blown through a jet into a tapered tube to create a vacuum. Air from the pump casing and suction line is drawn in with the compressed air and vented. A check valve seals the discharge line, allowing liquid to enter the pump body. This method has the advantage that the potential for blockages is reduced (because there is no priming chamber) and the pump can be run dry safely.

What are the Common Problems with Self-Priming Pumps?

The ability of a pump to self-prime can be affected by several factors. The discharge line must not be pressurized or blocked. With all types of pump, the suction line must be air-tight. If air continues to be drawn into the pump, the pressure is never reduced and fluid is not drawn up the suction line.

It is also important that the volume of the suction-side pipework is minimized to reduce the priming time. With excessive priming times, there is a danger that the liquid charge will evaporate before the pump is primed. The consequential dry-running may then cause damage to the pump.

In the case of centrifugal pumps, anything that affects the efficiency of the impeller will limit the self-priming ability. If the liquid contains any solids, debris may collect in the recirculation port, impeding the circulation of fluid and the generation of the liquid ring. Debris collecting on the impeller itself will reduce its ability to generate a low pressure region at the eye. Also, as a pump ages and succumbs to wear, the clearances between the impeller and volute case increase and the pump is less able to generate a low pressure zone. Internal clearances can also be affected by incorrect assembly after maintenance.

When pumping water in cold environments, it's important, if the temperature may fall below freezing, to drain a pump or to provide some form of heating. Damage may occur if water freezes in the pump or pipework.

Summary

Self-priming pumps are necessary if a pump has to be located above the level of the liquid to be pumped. A self-priming pump must be capable of evacuating air from the suction line, thereby drawing liquid into the pump. When this has been achieved, the pump can revert to its normal pumping mode.

Most types of positive displacement pumps are self-priming but care must be taken to avoid overheating, seal wear or cavitation during the dry-running, priming phase. Centrifugal pumps can be modified to be self-priming with a surrounding 'tank' to retain some of the fluid. Before use, it is crucial that the pump is filled correctly and not allowed to run dry at any stage.