Key Specifications / Features

Model No.: Hits: 66

Detail Information

Head(m): 0-50 m.

Applications: can suck paint, glue, grinding materials, various strong acid, alkali, corrosive liquid, etc.

Features

A aluminium alloy diaphragm pump can not only transport media which are not easily conveyed, but also has advantages of other pumps such as slurry pumps, self-pumping pumps, shield pumps, etc.

Suction lift reaches a height of 7m; the delivery lift reaches a length of 70m; output pressure ≧6kgf/cm2

Has good performance and great flow.

Can be soaked in media.

Has simple structure, easy installation and maintenance.

Can convey viscous liquid.

Oil lubricant is not required.

Has convenient and reliable operation.

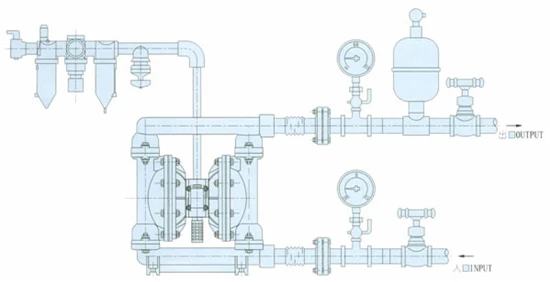

The connection schematic diagram for stainless steel diaphragm pumps

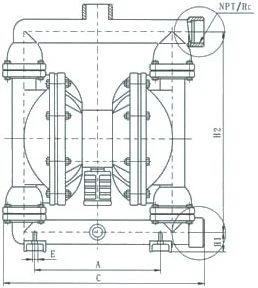

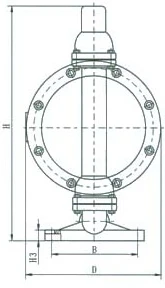

Stainless steel diaphragm pump drawing

Stainless steel diaphragm pump drawing

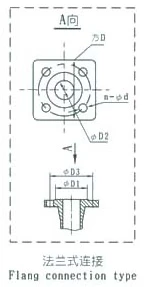

Stainless steel diaphragm pump drawing

More Information for Stainless Steel Diaphragm Pump

| Model | A | B | C | D | E | H1 | H2 | H3 | H | Screw | Flange | |||||

| NPT/RC | D1 | D2 | D3 | D | n | g | ||||||||||

| QBY-10 | 130 | 50 | 220 | 145 | 10 | 39 | 195 | 10 | 270 | 1/2 | - | - | - | - | - | - |

| QBY-15 | 130 | 50 | 220 | 145 | 10 | 39 | 195 | 10 | 270 | 1/2 | - | - | - | - | - | - |

| QBY-25 | 245 | 160 | 360 | 250 | 12 | 63 | 360 | 36 | 470 | 2 | - | - | - | - | - | - |

| QBY-40 | 245 | 160 | 360 | 250 | 12 | 63 | 360 | 35 | 470 | 11/2 11/4 | - | - | - | - | - | - |

| QBY-50 | 335 | 220 | 540 | 345 | 16 | 88 | - | 25 | 720 | - | 90 | 50 | 110 | 130-130 | 4 | 14 |

| QBY-65 | 335 | 220 | 540 | 345 | 16 | 88 | - | 25 | 720 | - | 110 | 65 | 130 | 130-130 | 4 | 14 |

| QBY-80 | 425 | 250 | 570 | 450 | 18 | 110 | - | 32 | 900 | - | 125 | 80 | 150 | 160-160 | 4 | 18 |

| QBY-100 | 425 | 250 | 570 | 450 | 18 | 110 | - | 32 | 900 | - | 145 | 100 | 170 | 160-160 | 4 | 18 |

Stainless Steel Diaphragm Pump Preformance Parameter

| Model | Discharge (m3/h) |

Head (m) |

Exit pressure (kgf/cm2) |

Sucked Lift (m) |

Max grain Dia (mm) |

Max pressure (kgf/cm2) |

Max air consumption (m3/min) |

Materials | ||||

| ZL104 | 1Cr18 Ni9Ti |

HT200 | Enhanced Polypr opyene |

F4 F46 (EFP)PO |

||||||||

| QBY-10 | 0-0.8 | 0-50 | 6 | 5 | 1 | 7 | 0.3 | * | * | * | * | / |

| QBY-15 | 0-1 | 0-50 | 6 | 5 | 1 | 7 | 0.3 | * | * | * | * | / |

| QBY-25 | 0-2.4 | 0-50 | 6 | 7 | 2.5 | 7 | 0.6 | * | * | * | * | |

| QBY-40 | 0-8 | 0-50 | 6 | 7 | 4.5 | 7 | 0.6 | * | * | * | * | * |

| QBY-50 | 0-12 | 0-50 | 6 | 7 | 8 | 7 | 0.9 | * | * | * | / | * |

| QBY-65 | 0-16 | 0-50 | 6 | 7 | 8 | 7 | 0.9 | * | * | * | / | * |

| QBY-80 | 0-24 | 0-50 | 6 | 7 | 10 | 7 | 1.5 | * | * | * | / | / |

| QBY-100 | 0-30 | 0-50 | 6 | 7 | 10 | 7 | 1.5 | * | * | * | / | / |